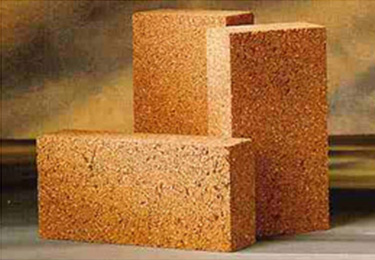

We are largest manufacturer and supplier of high quality acid resistant bricks, acid proof bricks, chemical resistant brick, anti acid bricks, anti abrasion bricks, acid alkali resistant bricks exporter in all over the world. Our acid resistant bricks are used for masonry constructions and floorings subject to acid attack, lining of chambers and towers in chemical plants, lining of sewers carrying industrial effluents and to prevent deterioration of the surface by acids except hydrofluoric acid and perchloric acids.

Acid resistant bricks are made of raw materials, such as clay of suitable composition with low lime and iron content, feldspar, flint or sand and vitrified at high temperatures in ceramic kilns. Durachem bricks are normally installed with chemical resistant mortars. They are available in different sizes and shapesbedded and jointed with acid proof cements. The cements used are depending on the chemical condition and temperature up to its specific limitations. We manufacture as per relevant IS/ASTM standards.

BRL Refractories designs acid proof bricks for specialized equipments where arch, corbel, coving dome shaped and tongue - groove bricks are used. We supply acid alkali resistant bricks in various shapes, sizes and thickness. Our standard thicknesses are 25mm, 40mm and 75mm but other thickness are manufactured as per request.

| IS 4860 ( Class I ) | Specification Characteristic |

|---|---|

| 2.5 | Warpage in mm, max |

| 2 | 2 |

| 700 | Compressive strength, kg/cm2 , min |

| 100 | Flexural strength kg/cm2 , min |

| 1.5 | % Resistance to acid, max |

| 2 | Resistance to wear, mm, max |

Copyright © 2021 BRL - All Rights Reserved.