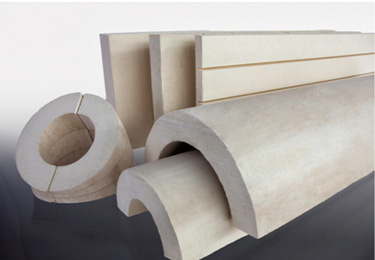

Magnesia bricks are basic refractory bricks used because of their high strength and heat resistant properties. Different grade magnesite is used as raw material and applied in magnesia bricks of various qualities. Magnesia bricks are mainly used in front and back wall of open hearth furnaces, electric arc furnace and for blast furnace & chemical industry.

| Magnesite | This range of fired and chemically bonded magnesite bricks is suitable for use in backup applications of steel ladle, EAF, any high temperature application above 1500°C. |

|---|---|

| Iron & Steel | Blast Furnaces & Hot Stoves of Blast Furnace |

| Magnesite Chrome | Conventional and dense fired conventional Magnesia chrome bricks are offered for utilities such as steel ladle, LRF, AOD, VOD, EAF for back up and working lining applications, melting furnace of copper industry. |

| Chrome Magnesite | Our range of general purpose varieties for backup application, reheating furnace and other non ferrous industries. Chrome magnesite bricks are offered for utilities such as steel ladle, LRF, AOD, VOD, EAF for back up and working lining applications, melting furnace of copper industry. |

| Direct Bonded | High grade magnesite chrome co-sinter and fired at a very high temperature. These are very good corrosion, erosion and thermal shock resistant bricks suitable for application in Copper Smelters, Lead & Zinc Furnaces, AOD working lining and other Non Ferrous applications. |

Spinels are flexibilizers which support flexibility in basic bricks – important for rotary kiln bricks affected by mechanical stress. Magnesia spinel based bricks are not sensitive to the formation of low melting calcium aluminate phases in the lining of the rotary kiln during clinker production.

We offer high quality spinel bricks sourced from leading manufacturers and factories strategically located near rich raw material belts to ensure low lead time and consistent quality.

Copyright © 2021 BRL - All Rights Reserved.