Fibre-reinforced plastic (FRP) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass, carbon, aramid, or basalt. FRP/GRP resists a wide range of chemicals and temperatures. Several resin systems suitable for specific corrosion conditions are available.

Glass fibre is available as chopped Strand Mat, Woven Roving, Roving and surface veils. A simple fabrication method namely hand layup is still the most preferred method for manufacturing for chemical plants equipments. Filament winding is done wherever additional load bearing requirement can be economically met. Dual laminates are more in use now and are FRP equipments thermoplastic corrosion resistant process face of PP, PVC, ECTFE, FEP, PVDF provide a combination of excellent chemical resistance of thermoplastics and moderate mechanical properties of FRP.

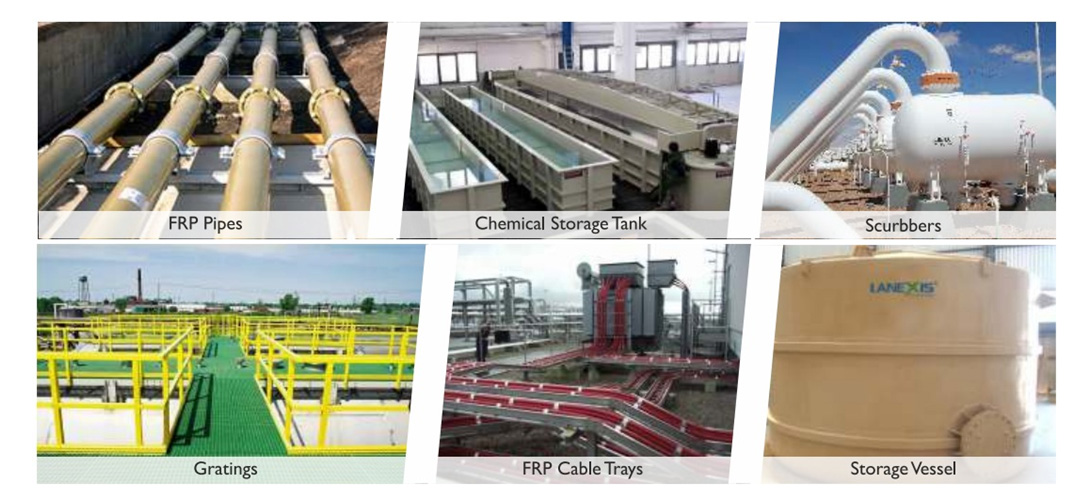

FRP PIPES- In the oil and gas production industry, high pressure applications include up to 4,000 psi. In environments as cold as above the Arctic Circle to the deserts of the Middle East. FRP piping is used both above ground and buried and is found in systems from Production to Enhanced Oil Recovery techniques, including hydraulic fracturing to salt water and CO2 injection.

CHEMICAL STORAGE TANK - These FRP Reaction Vessels & Storage Tanks are available in different shapes, sizes and with a capacity of 100kl/100 tons. These are found in various applications like chemical, bulk drugs, intermediates, electroplating etc. These are recognized for their features like Durable, different colors, leak proof/tested welding joints, dimensional stability, long service life.

SCRUBBERS - Scrubber systems are a diverse group of air pollution control devices that can be used to remove some participants and/or gases from industrial exhaust streams. Scrubbers are one of the primary devices that control gaseous emissions, especially acid gases. Scrubbers can also be used for heat recovery from hot gases by flue-gas condensation They are also used for the high flows in solar, PV, or LED processes.

FRP GRATINGS - Fiberglass reinforced plastic grating (also known as FRP grating, glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. Fiberglass grating does not corrode like steel grating and is therefore used in corrosive environments to reduce maintenance costs. It is used in a variety of applications including walkways and overhead platforms. FRP grating is a structural product that can be weight-bearing between spans.

STORAGE VESSEL - These are widely used in the chemical industry in the following sectors: chlor-alkali manufacturers, fertilizer, wood pulp and paper, metal extraction,refining, electroplating, brine, vinegar, food processing and in air pollution control equipment, especially at municipal wastewater treatment plants and water treatment plants.

FRP CABLE TRAYS - These are safe, durable and cost-effective for routing and supporting cables.

Copyright © 2021 BRL - All Rights Reserved.